2022-06-30 12:37 source: surging news, surging number, PAIKE

As we all know, new materials have been listed as one of the major directions of the “made in China 2025″ plan. As an important sub field, glass fiber is expanding rapidly.

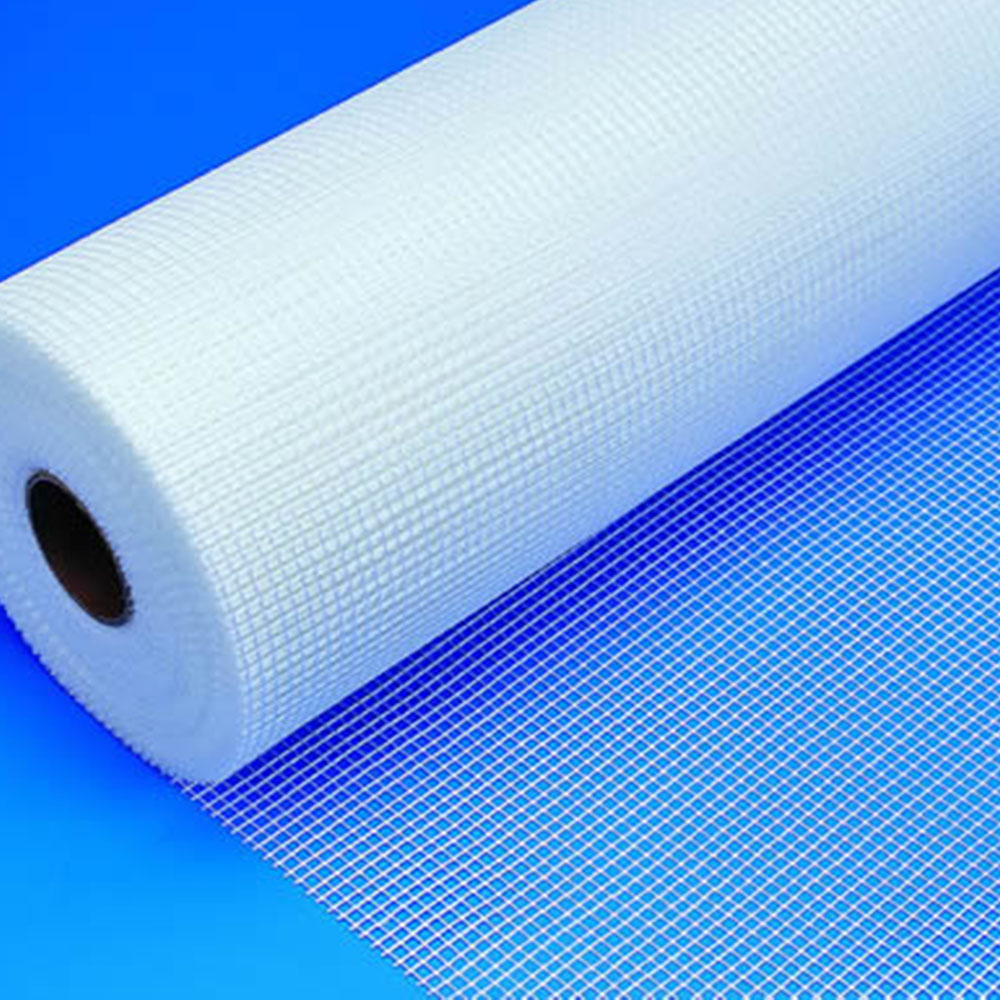

Glass fiber was born in the 1930s. It is an inorganic non-metallic material produced from main mineral raw materials such as pyrophyllite, quartz sand, limestone and chemical raw materials such as boric acid and soda ash. It has a series of advantages such as low cost, light weight, high strength, high temperature resistance and corrosion resistance. Its specific strength reaches 833mpa/gcm3, which is second only to carbon fiber (more than 1800mpa/gcm3) among common materials. It is an excellent functional and structural material.

Domestic market ushers in expansion period

Based on historical data, relevant institutions have calculated that the average growth rate of the glass fiber industry is generally 1.5-2 times the growth rate of the country’s GDP. Owens Corning found that the growth rate of global glass fiber demand is about 1.6 times that of industrial output by looking back at the data of the world from 1981 to 2015. The calculation results of Huatai Securities show that from 2006 to 2019, the growth rate of global glass fiber demand has a good linear relationship with the year-on-year growth of GDP and industrial added value. Among them, the growth rate of global glass fiber demand is about 1.81 times that of GDP and 1.70 times that of industrial added value. However, historical data show that in the past, the linear relationship between domestic glass fiber demand and macroeconomic indicators was weak. In recent years, the ratio of glass fiber demand growth to GDP growth was significantly higher than that of the world. In 2018 and 2019, the ratio was 2.4 and 3.0 respectively.

Tracing back to the source, this is directly related to the low penetration rate of glass fiber in China.

China’s per capita annual consumption of glass fiber is far lower than that of developed countries. In 2019, China’s per capita consumption of glass fiber was about 2.8kg, while that of the United States, Japan, the European Union and other developed countries was about 4.5kg.

The top three areas of fiberglass application in China are construction, electronics and appliances, and transportation, accounting for 34%, 21%, and 16% respectively.

Among them, the largest consumption direction of glass fiber in the field of electronics and appliances is the electronic cloth used to make copper clad laminate (CCL) in printed circuit (PCB), which consumes most of the electronic yarn (about 95%). Domestic electronic yarn is being replaced by domestic products, and the proportion of imports in China’s electronic yarn output has decreased year by year, and some high-end products are gradually replaced by imports.

With the continuous promotion of 5g commercial use, the demand for PCB has increased significantly. The large-scale construction of data centers and the large-scale demand for servers will become the biggest driving force driving the growth point of PCB market in the short term. Driverless and AI applications provide long-term demand support for PCB, and the electronic field will probably bring an incremental market for glass fiber in the future.

The trend of global energy and environmental policies makes traffic lightweight become a long-term issue in the industry. The application of lightweight materials such as glass fiber reinforced composites is one of the main ways, but there is a large gap between China and the world’s leading level. Germany, the United States and Japan are currently countries with a relatively high proportion of automotive lightweight materials. Among them, the application of automotive lightweight materials in Germany accounts for about 25%, which is the highest in the world. There is a large gap between the application of lightweight materials in Chinese cars and foreign advanced levels. For example, the consumption of aluminum and steel is about half of the international advanced level, and the consumption of magnesium alloy is about 1/10 of the European advanced level, China’s demand for automotive glass fiber still has great room for growth.

According to the data of China fiber composites network, in 2021, the national output of glass fiber reached 6.24 million tons, compared with 258000 tons in 2001, and the CAGR of China’s glass fiber industry in the past 20 years was as high as 17.3%. From the perspective of import and export data, the national export volume of glass fiber and products in 2021 was 1.683 million tons, with a year-on-year increase of 26.5%; The import volume was 182000 tons, maintaining a normal level.

Post time: Jul-11-2022